Revolutionizing Manufacturing: AI-Powered Assembly Line Monitoring with Matrice

May 20, 2025

Modern assembly lines are the backbone of mass production, operating at high speeds to deliver products that meet stringent quality standards. Traditional monitoring methods, often relying on manual inspection or basic sensors, can struggle to keep pace with the complexity and velocity of these operations, leading to potential defects, inefficiencies, and safety hazards. The integration of Artificial Intelligence and advanced computer vision technologies is now paving the way for a new era of automated assembly line monitoring, offering unprecedented precision and proactivity.

This blog post explores the critical need for robust assembly line monitoring, the implementation of the cutting-edge RT-DETR-X model for this application, and the transformative benefits it brings to manufacturing environments.

1. Why Automated Assembly Line Monitoring Matters

In the competitive landscape of modern manufacturing, ensuring flawless production is paramount. Automated monitoring systems play a vital role in achieving this by addressing several key aspects:

Enhanced Quality Control: Real-time identification of product defects, component misplacements, or deviations from assembly standards ensures that only quality products proceed through the line.

Increased Operational Efficiency: Minimizes production downtime by rapidly detecting process anomalies, material misfeeds, or equipment malfunctions, allowing for swift corrective action.

Improved Throughput: Optimizes the flow of operations by ensuring each step is completed correctly, reducing bottlenecks and rework.

Worker Safety: Monitors for unsafe conditions, incorrect human-machine interactions, or the absence of safety gear, contributing to a safer working environment.

Waste Reduction: Early detection of defects or process errors reduces material waste and the cost associated with scrapping or reworking faulty products.

Process Optimization: Gathers data on assembly processes, which can be analyzed to identify areas for improvement, enhance cycle times, and streamline workflows.

The ability to instantly detect and classify various states, components, and potential anomalies on a fast-moving assembly line is crucial for maintaining high productivity and quality standards.

2. Benefits of AI in Assembly Line Monitoring

AI-powered systems, particularly those utilizing sophisticated object detection models like RT-DETR-X, bring a host of advantages to assembly line monitoring:

Real-time Anomaly Detection: Continuous, high-speed visual inspection allows for the immediate flagging of deviations from the norm, far exceeding human capabilities.

Superior Accuracy and Consistency: AI models provide objective and repeatable assessments, free from human fatigue or subjective judgment, leading to more reliable quality assurance.

24/7 Uninterrupted Operation: AI systems can monitor production lines around the clock, ensuring consistent oversight without breaks.

Handling Complex Scenarios: Capable of identifying subtle defects or monitoring intricate assembly processes involving numerous small components under varied lighting conditions.

Data-Driven Insights & Predictive Capabilities: Accumulates vast amounts of operational data that can be used for trend analysis, root cause analysis of defects, and even predictive maintenance alerts for machinery.

Scalability and Adaptability: AI models can be trained to recognize new products or defects, allowing monitoring systems to adapt to changing production needs.

3. Implementing Assembly Line Monitoring with RT-DETR-X

To address the challenges of assembly line monitoring, we focused on deploying a robust object detection system. While various architectures like YOLO, ResNet, and MobileNet offer solutions, the RT-DETR-X model was chosen for its exceptional balance of real-time performance and high accuracy.

Dataset Preparation

A specialized dataset, “assembly-line-monitoring v1.0”, was curated to train and evaluate the model effectively for this detection problem:

Dataset Name:

assembly-line-monitoringVersion:

v1.0Data Split:

Training images: 1,086

Validation images: 310

Test images: 155

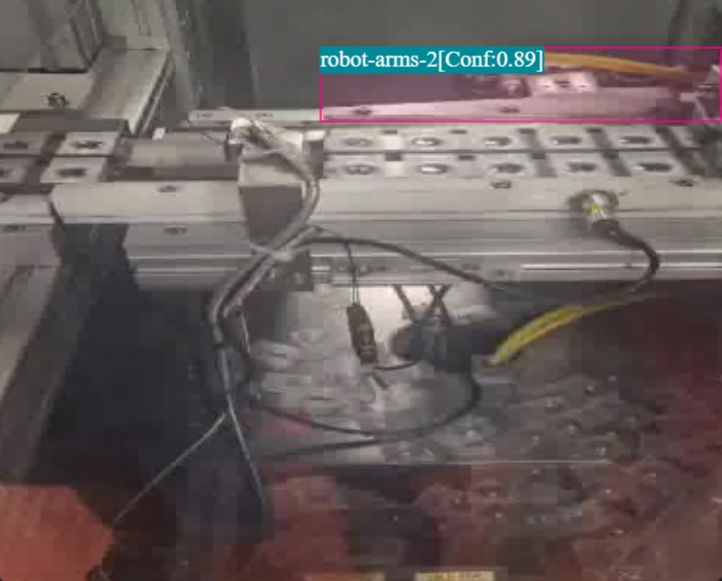

Content Diversity: The dataset comprises images capturing a variety of assembly line scenarios. It includes annotations for specific components and states such as ‘metal-plate’ (indicating a plate with components), ‘metal-plate-empty’ (a plate awaiting components), and various robotic elements like ‘robot-arms’, ‘robot-arms-2’, and ‘robot-arms-3’. This allows the model to learn to differentiate these states, detect correct configurations, and identify potential anomalies (e.g., a ‘metal-plate’ that should be ‘metal-plate-empty’ or vice-versa, or issues with robotic arm positioning). Images were captured under typical industrial lighting and from various viewpoints.

Annotation: Objects of interest and anomalies were meticulously annotated with bounding boxes for the detection task.

Model Architecture: RT-DETR-X

The RT-DETR-X (Real-Time Detection Transformer - Extra Large variant, adapted), developed by Baidu, was selected as the core of our monitoring system. Despite its powerful capabilities, the specific version used is optimized for efficiency.

Model Family: RT-DETR

Key Strengths:

End-to-End Detection: Provides a streamlined, transformer-based architecture that requires less post-processing (like NMS) compared to many traditional detectors.

Real-Time Performance: Engineered for high-speed inference, making it ideal for live monitoring of dynamic assembly lines.

High Accuracy: Maintains strong detection accuracy even at high speeds.

Efficient Design: The chosen variant has 11.2 million parameters, offering a remarkable balance between model complexity and performance.

Benchmark Performance: This model architecture (or its close family members) demonstrates strong performance, with variants achieving a COCO val mAP of 54.8%, indicating its robust feature extraction and detection capabilities on general-purpose object detection tasks.

Training Framework: PyTorch

Training Parameters

The RT-DETR-X model was trained on the “assembly-line-monitoring v1.0” dataset using the following configuration:

Parameter |

Value |

Description |

|---|---|---|

Base Model |

RT-DETR-X |

Real-Time Detection Transformer |

Batch Size |

4 |

Number of images processed per training step |

Learning Rate |

0.001 |

Initial step size for the optimizer |

Epochs |

30 |

Number of full passes through the training dataset |

Optimizer |

auto |

Automatically selected (e.g., AdamW by Ultralytics framework) |

Momentum |

0.95 |

Used if optimizer is SGD-based (often part of ‘auto’) |

Weight Decay |

0.0005 |

Regularization to prevent overfitting |

Cosine LR Scheduler |

False |

Linear or step learning rate decay was used |

Primary Metric |

Precision |

Focus on minimizing false positives in detections |

Target Runtime |

PyTorch |

Framework for model execution |

Model Evaluation

The model’s performance was rigorously evaluated on the validation and test sets. The primary metric was Precision, ensuring that detected anomalies or components were indeed correct.

Validation Results:

Metric |

All Categories |

|---|---|

Precision |

0.95 |

Recall |

0.94 |

mAP@50 |

0.97 |

mAP@50-95 |

0.72 |

Test Results (Primary Performance Indicators):

Metric |

All Categories |

|---|---|

Precision |

0.966791 |

Recall |

0.95 |

F1 Score |

0.95 |

mAP@50 |

0.96 |

mAP@50-95 |

0.69 |

(F1 Score calculated as 2 * (Precision * Recall) / (Precision + Recall) for “All Categories” on test results)

The outstanding test precision of 0.967 demonstrates the model’s reliability in accurately identifying relevant events and objects on the assembly line. High recall and mAP scores further confirm its effectiveness.

Model Inference Results

Typical outputs of the RT-DETR-X system on the assembly line are:

Deployment Strategy

Effective deployment is key to realizing the benefits of the AI model:

Edge Computing: Deploying the RT-DETR-X model on industrial PCs or edge devices located near the assembly line cameras for minimal latency and real-time processing.

Camera Integration: Strategic placement of high-resolution industrial cameras covering critical inspection points.

MES/SCADA Integration: Connecting the AI system’s outputs (detected anomalies, quality flags, counts of items like ‘metal-plate’ or status of ‘robot-arms’) with Manufacturing Execution Systems (MES) or SCADA systems for automated data logging, process control adjustments, and dashboard visualization.

Alerting System: Configuring automated alerts (e.g., visual signals, notifications to supervisors) when critical defects or process deviations (e.g., incorrect ‘metal-plate-empty’ status) are detected.

Continuous Learning Loop: Periodically retraining the model with new data, especially examples of new defect types or product variations, to maintain and improve performance over time.

4. Real-World Applications and Impact

The implementation of AI-driven monitoring with RT-DETR-X can transform various aspects of assembly line operations:

Automated Defect Detection

Identifies scratches, dents, misalignments, missing parts (e.g. on a ‘metal-plate’), incorrect labeling, and other visual imperfections in real-time.

Reduces the escape of faulty products, improving customer satisfaction and brand reputation.

Component Verification and Counting

Ensures all necessary components are present and correctly assembled; for example, verifying that a ‘metal-plate’ has been processed (is not ‘metal-plate-empty’) or that ‘robot-arms’ have completed their tasks before the next stage.

Automates parts counting for inventory and kitting verification.

Process Compliance Monitoring

Verifies that assembly steps, including operations by ‘robot-arms’, are performed in the correct sequence and according to specifications.

Monitors cycle times for different operations to identify bottlenecks.

Safety Monitoring

Detects improper use of machinery, incorrect positioning of ‘robot-arms’, or entry into hazardous zones.

Ensures workers are using appropriate personal protective equipment (PPE).

Packaging and Labeling Inspection

Confirms correct packaging, verifies label information, barcode readability, and seal integrity before products are shipped.

5. Future Developments

The journey of AI in manufacturing is continuously evolving. Future advancements in assembly line monitoring may include:

Advanced Anomaly Detection: Moving beyond predefined defects to unsupervised methods that can detect novel or rare anomalies related to components like ‘metal-plate’ or ‘robot-arms’ without prior explicit training.

Predictive Quality Analytics: Using historical data to predict potential quality issues or machine failures before they occur.

Robotics Integration: Guiding ‘robot-arms’ for automated rework of detected defects or for adaptive assembly based on real-time visual feedback.

Digital Twin Integration: Feeding real-time visual data (including status of ‘metal-plate’, ‘robot-arms’) into digital twin models of the assembly line for comprehensive simulation, analysis, and optimization.

Multi-Sensor Fusion: Combining visual data with inputs from other sensors (e.g., thermal, acoustic) for more robust and comprehensive monitoring.

Explainable AI (XAI): Providing clearer insights into why the AI model flags certain items as defects, aiding in process improvement and operator trust.

Conclusion

Automated assembly line monitoring powered by AI models like RT-DETR-X represents a significant leap forward for the manufacturing industry. By providing fast, accurate, and consistent visual inspection capabilities for diverse elements including ‘metal-plates’ and ‘robot-arms’, these systems drive substantial improvements in quality control, operational efficiency, and workplace safety. The impressive performance of RT-DETR-X on the “assembly-line-monitoring” dataset underscores the readiness of such technologies to tackle complex real-world manufacturing challenges, paving the way for smarter, more autonomous, and highly efficient factories of the future.

📥 Resources (Illustrative)

RT-DETR Original Paper: Baidu Research - RT-DETR (Link to the foundational paper)

Training Framework: Ultralytics - YOLO and RT-DETR Implementations

Think CV, Think Matrice

Experience 40% faster deployment and slash development costs by 80%