Date: 2025-05-26

Enhancing Quality Control with Bottle Defect Detection on Matrice

Defect detection in manufacturing lines is a critical aspect of quality assurance. With AI-powered computer vision, it becomes possible to automate bottle defect identification, ensuring consistency and reducing manual inspection errors.

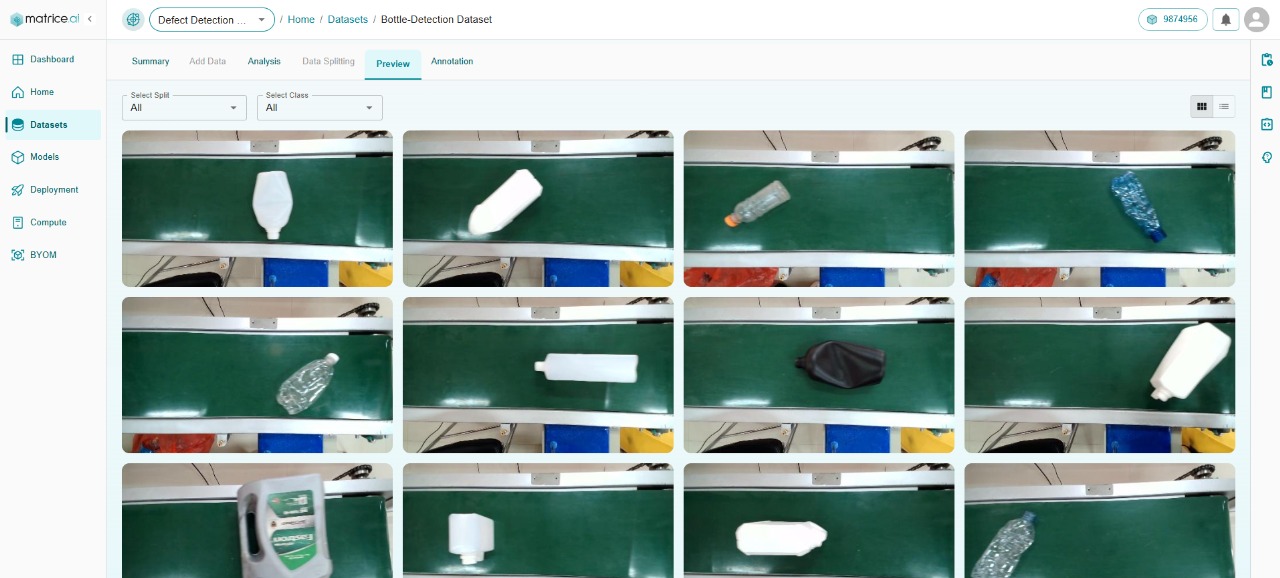

Our application focuses on detecting and localizing defects in bottles using a dedicated dataset. By training a model on images of bottles with visible defects, we enable precise identification of issues such as cracks, dents, and misalignments in real time.

This blog covers our approach to bottle defect detection using deep learning, including:

Dataset Preparation

Dataset Annotation

Model Training

Model Evaluation

Model Inference

Model Deployment

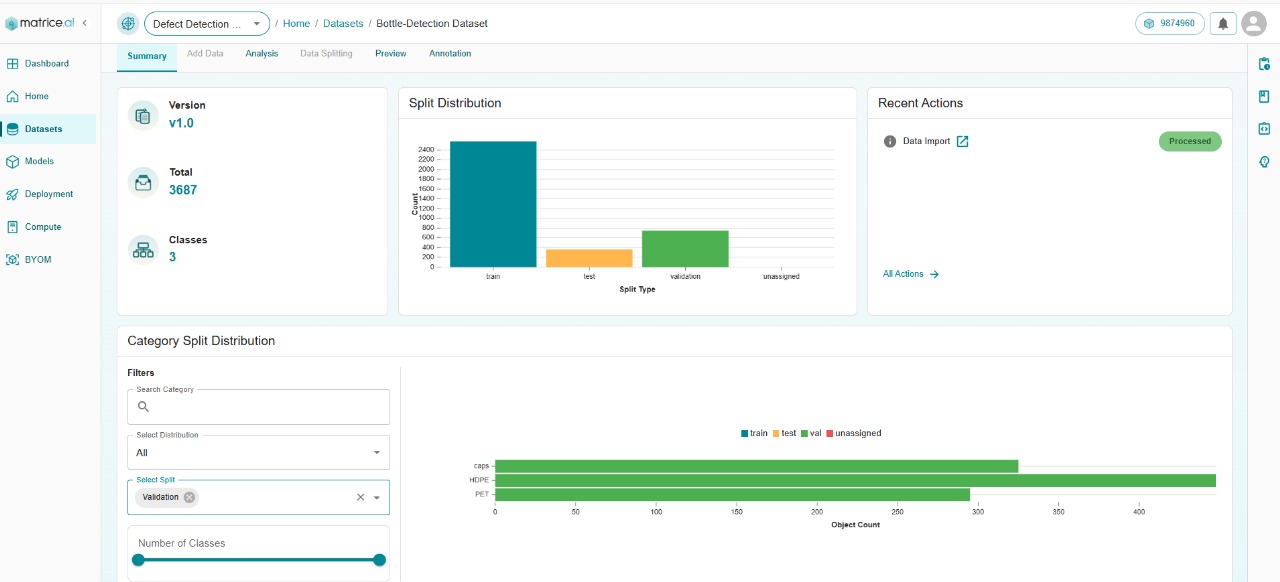

Dataset Preparation

The dataset for this project consists of images focused on different types of bottle defects. It includes only one category: bottle-defect. It is structured as follows:

Data Items: 3687

Training Set: 2576

Validation Set: 744

Testing Set: 367

This dataset is split in a 70:20:10 ratio to enable proper training, validation, and final testing.

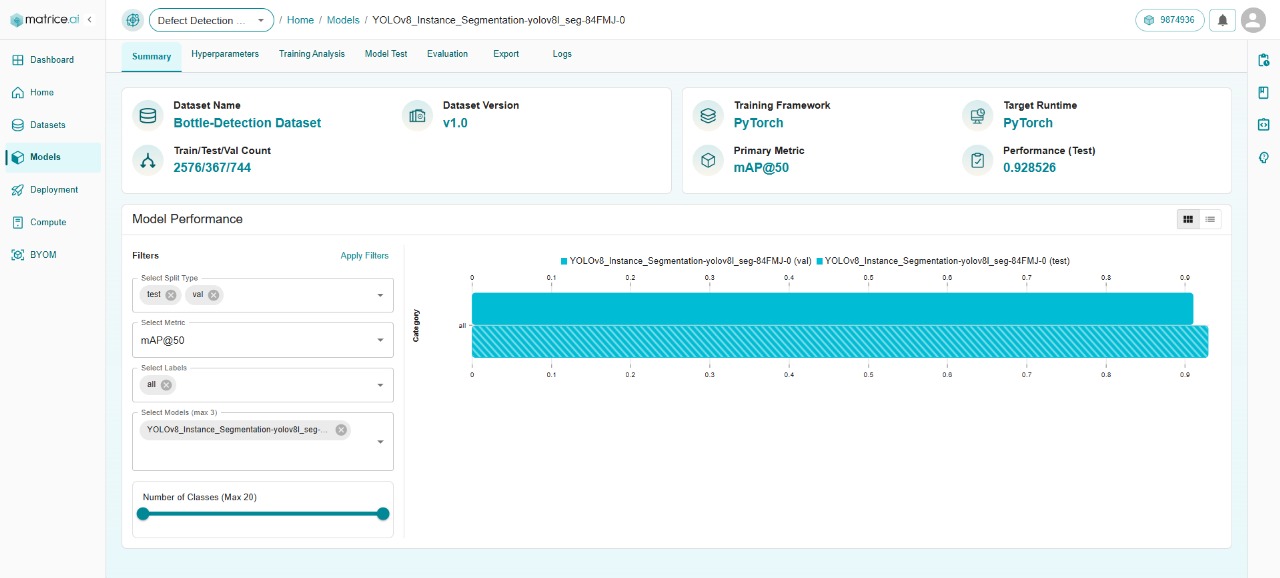

Model Training

We trained a YOLO-based Instance Segmentation model to detect defects with high precision and speed. The training parameters were selected based on experimentation to achieve the best results.

Batch Size: 2

Epochs: 50

Learning Rate (lr): 0.001

Optimizer: auto

Momentum: 0.95

Weight Decay: 0.0005

Performance Metrics

The trained model was evaluated on validation and test datasets, using metrics such as precision and recall to gauge effectiveness.

Metric |

Value (test) |

Value (Val) |

|---|---|---|

mAP@50 |

0.93 |

0.91 |

Precision |

0.92 |

0.931 |

Model Inference

The trained model can be exported to multiple formats for deployment on different hardware configurations.

Available formats:

PyTorch (.pt)

ONNX

TensorRT

OpenVINO

This flexibility enables real-time inspection even on edge devices in factory environments.

Model Deployment

Deploying the model on Matrice is straightforward. The platform offers real-time inference, API integration, and UI dashboards for inspection monitoring.

Applications include:

Automated inspection lines

Smart factory quality control

Production logging and alerts

Conclusion

By automating bottle defect detection, manufacturers can significantly reduce inspection time and human error while maintaining high-quality standards. With Matrice, you can bring powerful AI models into your workflow in just a few steps.

Think CV, Think Matrice

Experience 40% faster deployment and slash development costs by 80%