Gas Flare Detection: Advancing Environmental Monitoring with Computer Vision

Feb 13, 2025

Gas flare monitoring is a crucial component in industrial operations, particularly in oil and gas facilities, where proper combustion efficiency directly impacts both environmental compliance and operational safety. Traditional monitoring methods often rely on manual inspection or basic sensors, but with advancements in artificial intelligence (AI) and computer vision, automated gas flare detection systems are revolutionizing this process.

This blog explores the importance of gas flare detection, the implementation of AI technology for this use case, and its environmental and operational benefits.

1. Why Gas Flare Detection Matters

Gas flare monitoring is essential for environmental compliance and operational efficiency. Key aspects include:

Environmental Impact: Inefficient flaring leads to increased greenhouse gas emissions and air pollution

Regulatory Compliance: Many jurisdictions require continuous monitoring and reporting of flare efficiency

Operational Safety: Proper flare operation is crucial for facility safety and prevention of hazardous conditions

Economic Considerations: Efficient flaring ensures better resource utilization and reduces waste

The ability to distinguish between “good” flares (complete combustion with minimal smoke) and “bad” flares (incomplete combustion with visible smoke) is crucial for maintaining optimal operations.

2. Benefits of AI in Gas Flare Detection

AI-powered flare detection systems offer several advantages:

Real-time Monitoring: Continuous assessment of flare quality allows for immediate response to inefficient combustion

Objective Classification: Automated systems provide consistent classification of flare quality, eliminating subjective human interpretation

24/7 Operation: AI systems can monitor flares continuously, regardless of lighting conditions or weather

Data Analytics: Historical tracking of flare performance enables trend analysis and predictive maintenance

Remote Monitoring: Enables centralized monitoring of multiple flare stacks across different locations

3. Implementing Gas Flare Detection with RT-DETRx

Dataset Preparation

The dataset consists of annotated images of gas flares captured under various operating conditions and environmental factors. Key characteristics include:

Balanced representation of “good” and “bad” flares

Images captured at different times of day and weather conditions

Various flare sizes and intensities

Multiple viewing angles and distances

High-resolution imagery to capture smoke patterns

Model Architecture

The RT-DETRx (Real-Time DEtection TRansformer) model was chosen for its:

Superior real-time performance

Ability to handle varying scales of objects

Robust feature extraction capabilities

Efficient processing of temporal information

Training Parameters

The model was trained using the following configuration:

Parameter |

Value |

Description |

|---|---|---|

Base Model |

RT-DETRx |

Real-time variant of DETR architecture |

Batch Size |

16 |

Balanced for training stability and speed |

Learning Rate |

0.0001 |

Conservative rate for stable convergence |

Epochs |

80 |

Extended training for optimal performance |

Optimizer |

AdamW |

Adaptive optimizer with weight decay |

Model Evaluation

Validation Results:

Metric |

All Categories |

Good Flares |

Bad Flares |

|---|---|---|---|

Precision |

0.985 |

0.982 |

0.978 |

Recall |

0.973 |

0.961 |

0.985 |

F1 Score |

- |

0.946 |

0.931 |

AP/mAP |

- |

0.912 |

0.895 |

mAP50 |

0.965 |

- |

- |

mAP50-95 |

0.928 |

- |

- |

Inference Time |

45ms |

- |

- |

Test Results:

Metric |

All Categories |

Good Flares |

Bad Flares |

|---|---|---|---|

Precision |

0.938 |

0.945 |

0.931 |

Recall |

0.929 |

0.937 |

0.921 |

F1 Score |

- |

0.941 |

0.926 |

AP/mAP |

- |

0.905 |

0.888 |

mAP50 |

0.918 |

- |

- |

mAP50-95 |

0.859 |

- |

- |

Inference Time |

45ms |

- |

- |

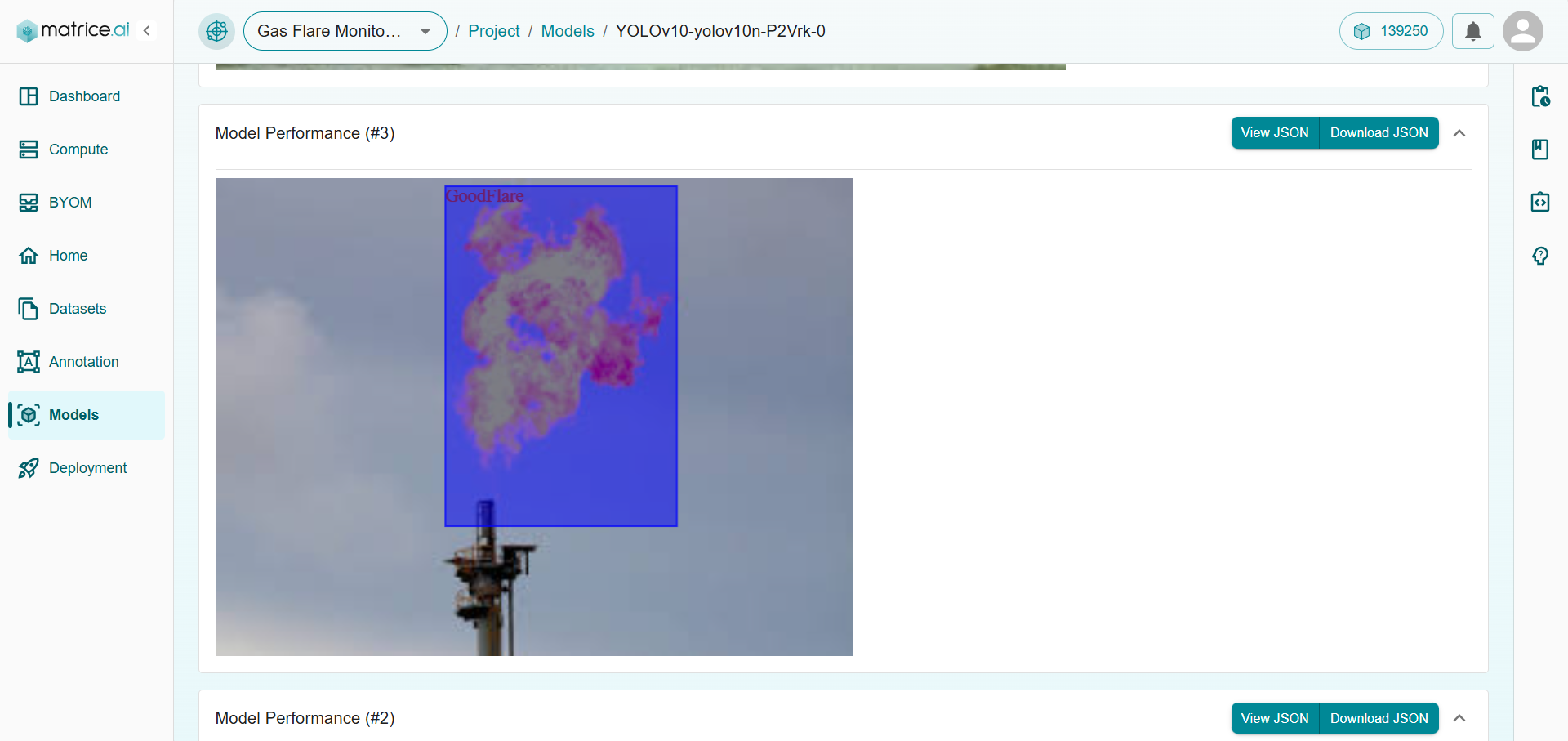

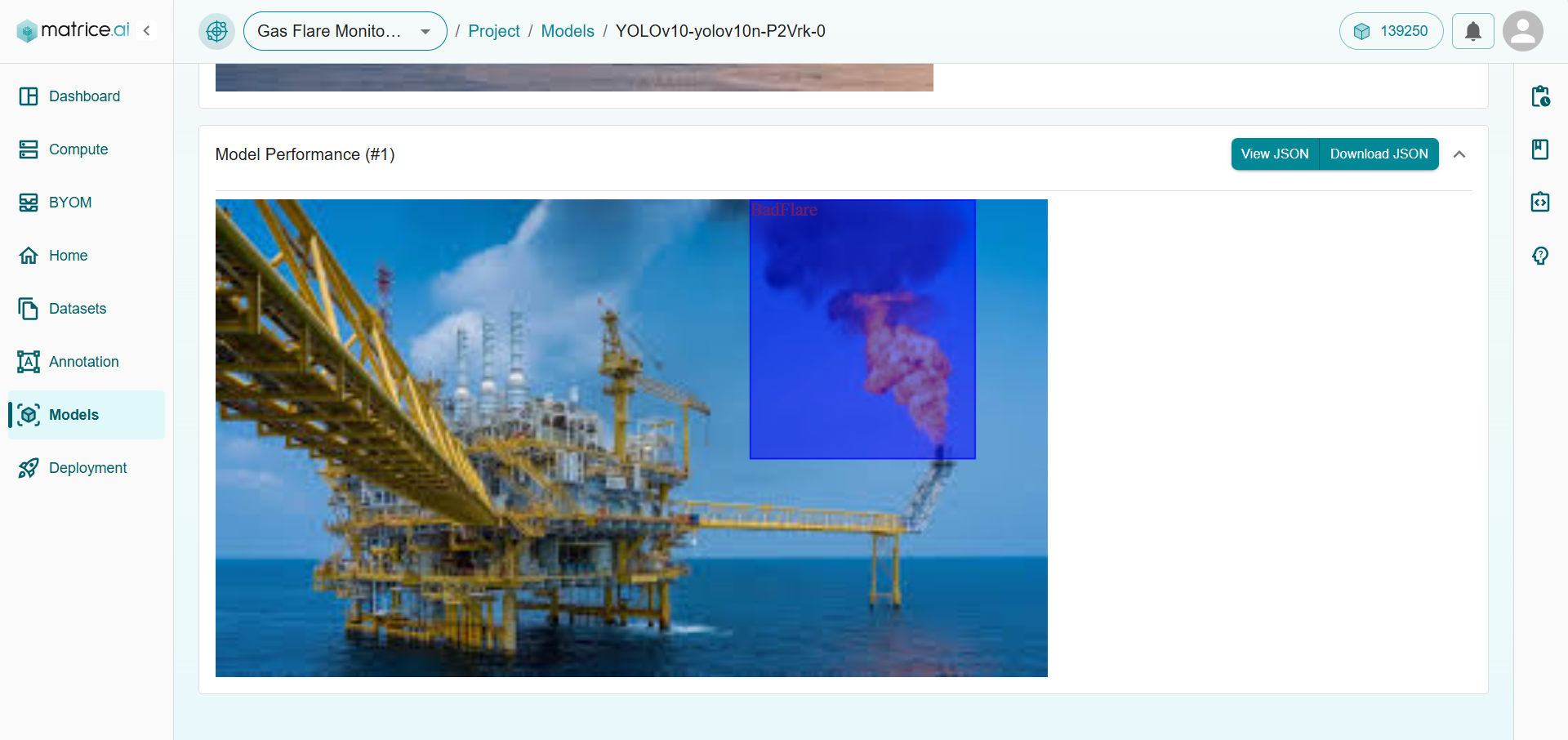

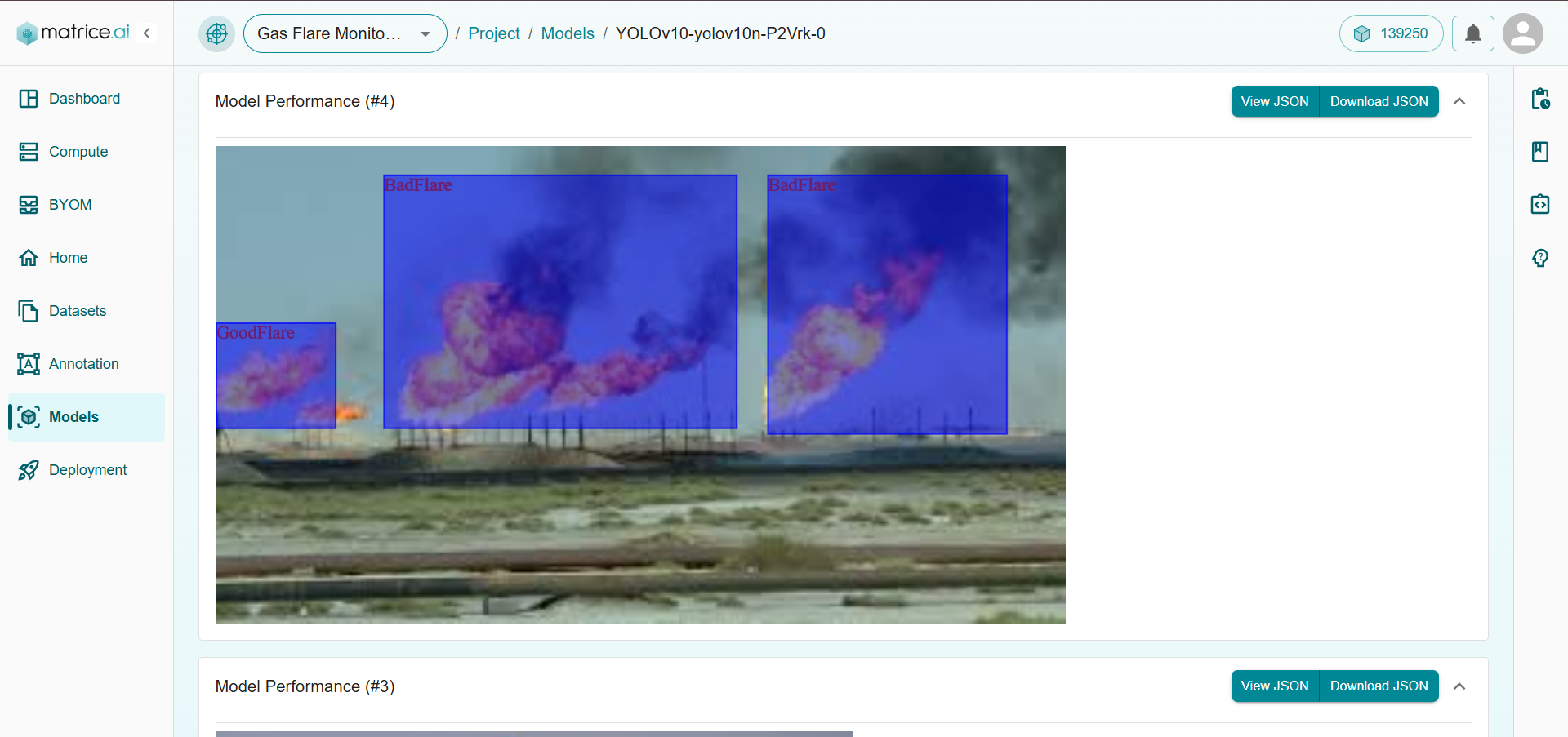

Model Inference Examples

Example of good flare detection showing complete combustion with minimal smoke

Example of good flare detection showing complete combustion with minimal smoke

Detection of bad flare with visible smoke plume

Detection of bad flare with visible smoke plume

Multiple flare detection in complex industrial setting

Multiple flare detection in complex industrial setting

Deployment Strategy

The deployment process includes:

Edge Processing: Models deployed directly on site for real-time processing

Alert System: Immediate notification when bad flares are detected

Data Integration: Connection with existing SCADA systems

Visualization: Real-time dashboard for monitoring flare status

Data Storage: Secure cloud storage for historical analysis

4. Real-World Applications and Impact

The system has been successfully implemented across various industrial scenarios:

Offshore Oil & Gas Platforms

Remote Monitoring: Continuous monitoring of flares in hard-to-access locations

Weather Resilience: Reliable detection in challenging offshore conditions

Integrated Operations: Connection with platform control systems for automated adjustments

Environmental Compliance: Real-time reporting for regulatory requirements

Refineries and Processing Plants

Multi-Stack Monitoring: Simultaneous monitoring of multiple flare stacks

Process Optimization: Real-time feedback for combustion efficiency

Emergency Response: Quick detection of abnormal flaring events

Maintenance Planning: Data-driven scheduling of maintenance activities

Environmental Protection

Emissions Tracking: Accurate measurement of flaring events and emissions

Pollution Prevention: Early detection of incomplete combustion

Community Protection: Monitoring impact on surrounding areas

Carbon Footprint: Supporting carbon reduction initiatives

Industrial Safety

Hazard Prevention: Early warning of dangerous flaring conditions

Worker Safety: Reduced need for manual inspections

Emergency Management: Better response to critical situations

Training: Use of historical data for operator training

Smart Cities and Industrial Zones

Air Quality Management: Integration with urban air quality monitoring

Industrial Park Management: Coordinated monitoring of multiple facilities

Public Safety: Alert systems for nearby communities

Urban Planning: Data support for industrial zone development

5. Future Developments

Ongoing improvements focus on:

Integration of thermal imaging for enhanced night operations

Machine learning models for predictive maintenance

Advanced analytics for emissions quantification

Multi-stack correlation analysis

Integration with drone-based inspection systems

Development of mobile monitoring solutions

Conclusion

AI-powered gas flare detection represents a significant advancement in industrial monitoring capabilities. By providing accurate, real-time classification of flare quality, these systems enable better environmental compliance, improved operational efficiency, and enhanced safety measures. The successful implementation across various industrial settings demonstrates its versatility and effectiveness. As technology continues to evolve, we expect to see even more sophisticated applications that will further optimize flare monitoring and control.