Improving Fruit Quality with Banana Defect Detection on Matrice

Bananas are one of the most consumed fruits globally, making quality control during post-harvest processing essential. Detecting defects like bruises, cuts, black spots, and rot is critical for ensuring shelf-life, customer satisfaction, and export quality.

Using Matrice’s no-code AI platform, we developed a banana defect detection system powered by YOLOv9 to automate the quality inspection process.

This blog explains the steps involved in building this AI-based solution:

Dataset Preparation

Dataset Annotation

Model Training

Model Inference

Model Deployment

Dataset Preparation

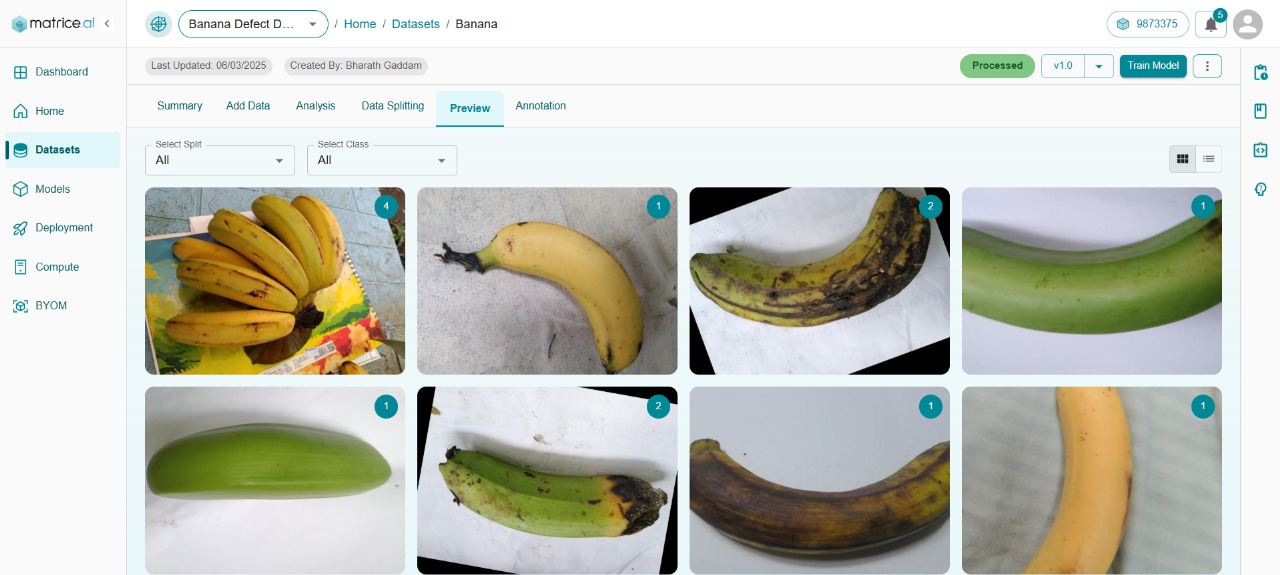

The dataset consists of annotated images of bananas showing various defect types:

Bruises

Black Spots

Peel Damage

Mold or Rot

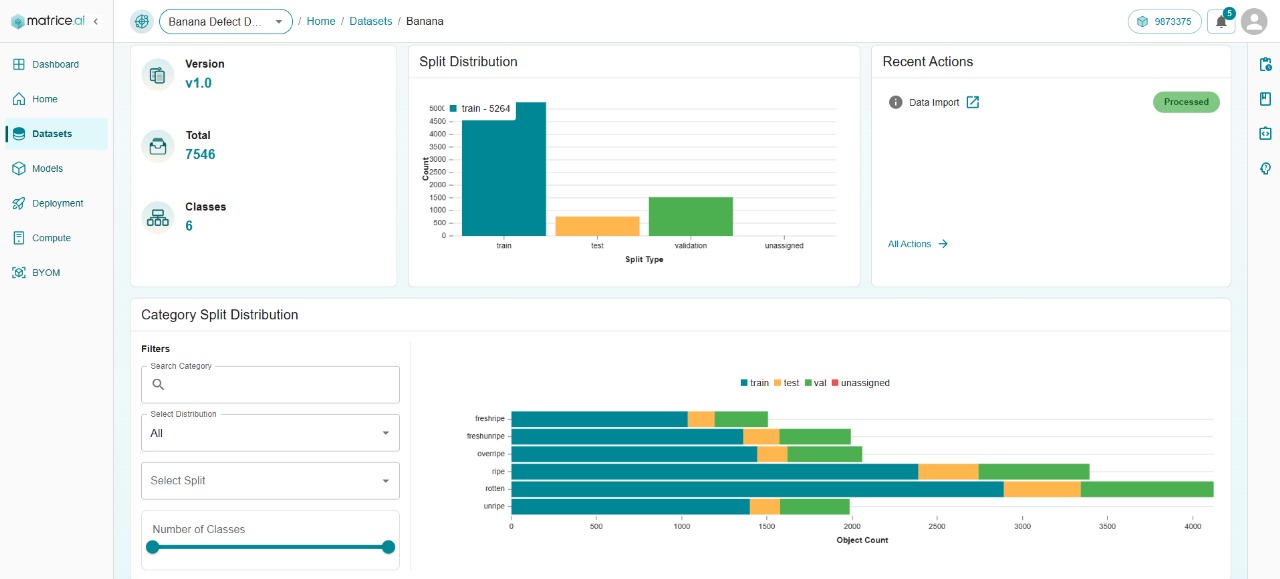

Total Images: 7,546

Training Set: 5,264 images

Validation Set: 1,525 images

Test Set: 757 images

Each image includes bounding box labels for defect regions.

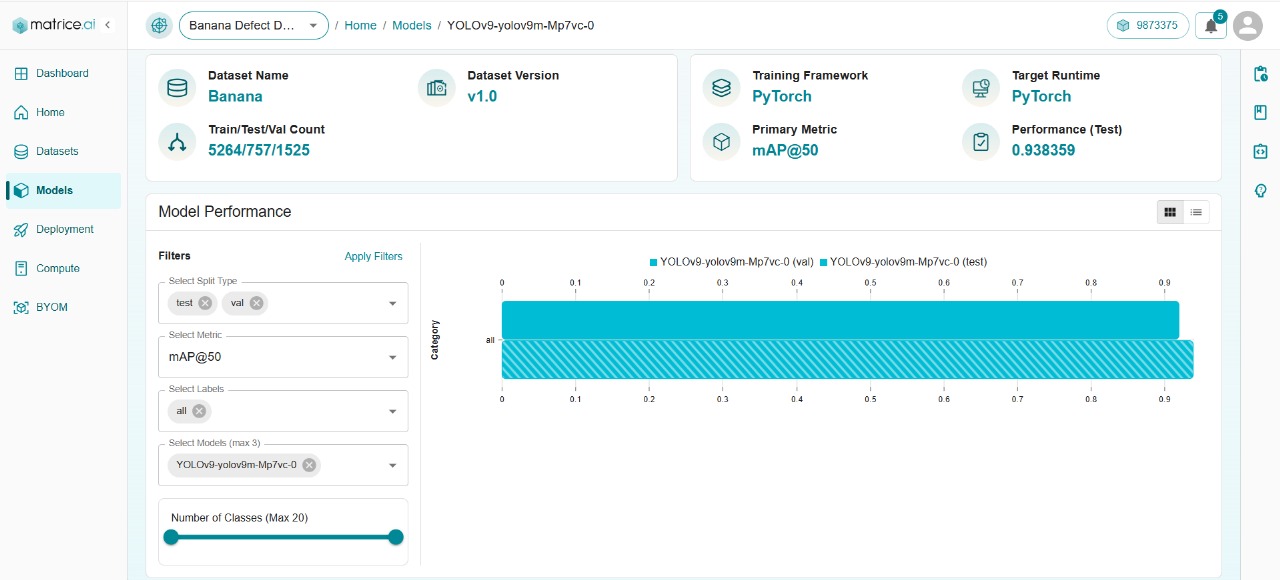

Model Training

A YOLOv9 object detection model was trained to recognize multiple defect categories on bananas.

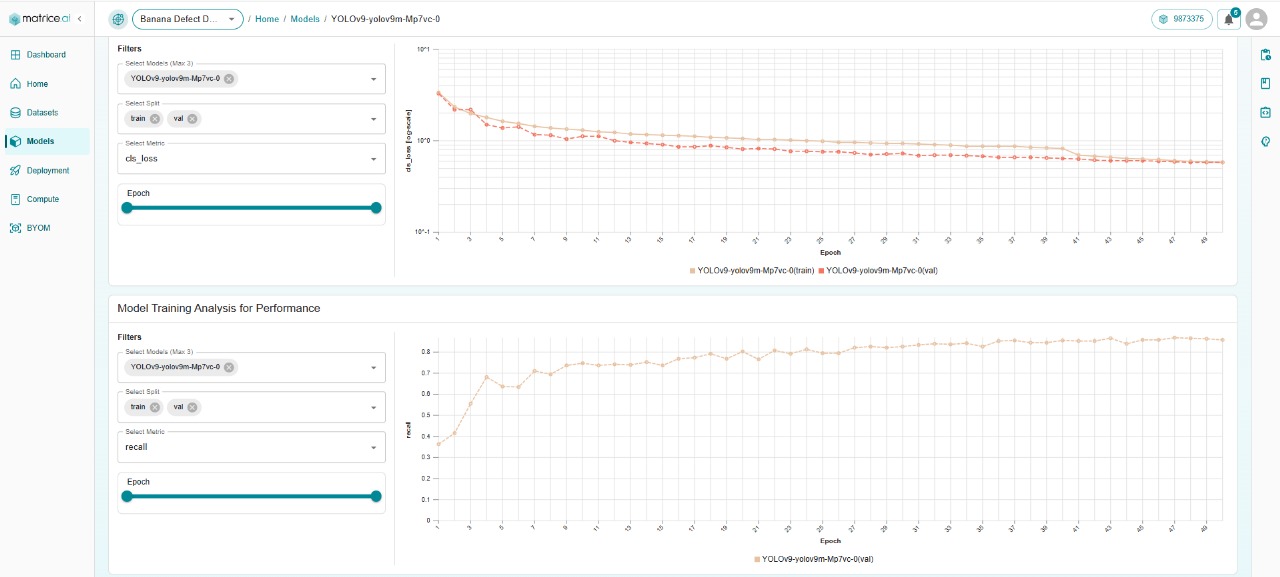

Batch Size: 16

Epochs: 50

Learning Rate: 0.001

Optimizer: Auto

Momentum: 0.95

Weight Decay: 0.0005

The model demonstrates robust performance in real-world scenarios such as packing stations or sorting lines.

Model Inference

The model can be exported in formats like:

PyTorch (.pt)

ONNX

TensorRT

OpenVINO

This allows seamless integration into edge-based visual inspection systems or cloud-based analytics platforms.

Model Deployment

With Matrice, the deployment process becomes effortless. Users can:

Run real-time detection in sorting or packaging lines

Visualize results on a dashboard

Trigger alerts for defective produce

Use Cases:

Post-harvest fruit grading in banana processing units

Automated rejection of defective fruits

Quality tracking for export batches

Conclusion

AI-powered defect detection helps reduce fruit wastage, ensure consistent quality, and streamline operations. Matrice allows agri-tech teams to deploy high-performing models without writing code—speeding up innovation in food quality management.

Think CV, Think Matrice

Experience 40% faster deployment and slash development costs by 80%