Worker Safety Detection with Matrice: Ensuring Safety on the Job Site

Workplace safety is a critical concern across various industries, with risks ranging from falls and machinery accidents to exposure to hazardous substances. Ensuring that workers comply with safety protocols, such as wearing helmets and protective gear, is vital in reducing accidents. By using computer vision, organizations can now monitor safety compliance in real-time, quickly identifying risks and alerting supervisors to take corrective action before incidents occur.

This article will guide you through the process of building a worker safety detection model using Matrice’s no-code platform. We’ll cover each step, from dataset preparation to model deployment, showing how this solution can help monitor and improve safety on job sites by identifying unsafe behaviors or missing protective gear.

Dataset Preparation

1. Dataset Preview

To develop an effective worker safety detection model, we need a dataset with images representing various safety compliance and non-compliance scenarios. For this project, we’ve prepared a dataset with images labeled across several categories:

Wearing Helmet (helmet)

No Helmet (no_helmet)

Wearing Reflective Vest (vest)

No Reflective Vest (no_vest)

Person (person)

We split the dataset into training, validation, and test sets in a 80:10:10 ratio, ensuring enough data for learning, validation, and testing. This split allows the model to generalize well and reliably detect worker safety compliance in diverse situations.

2. Categorical Distribution of Dataset

Dataset Annotation

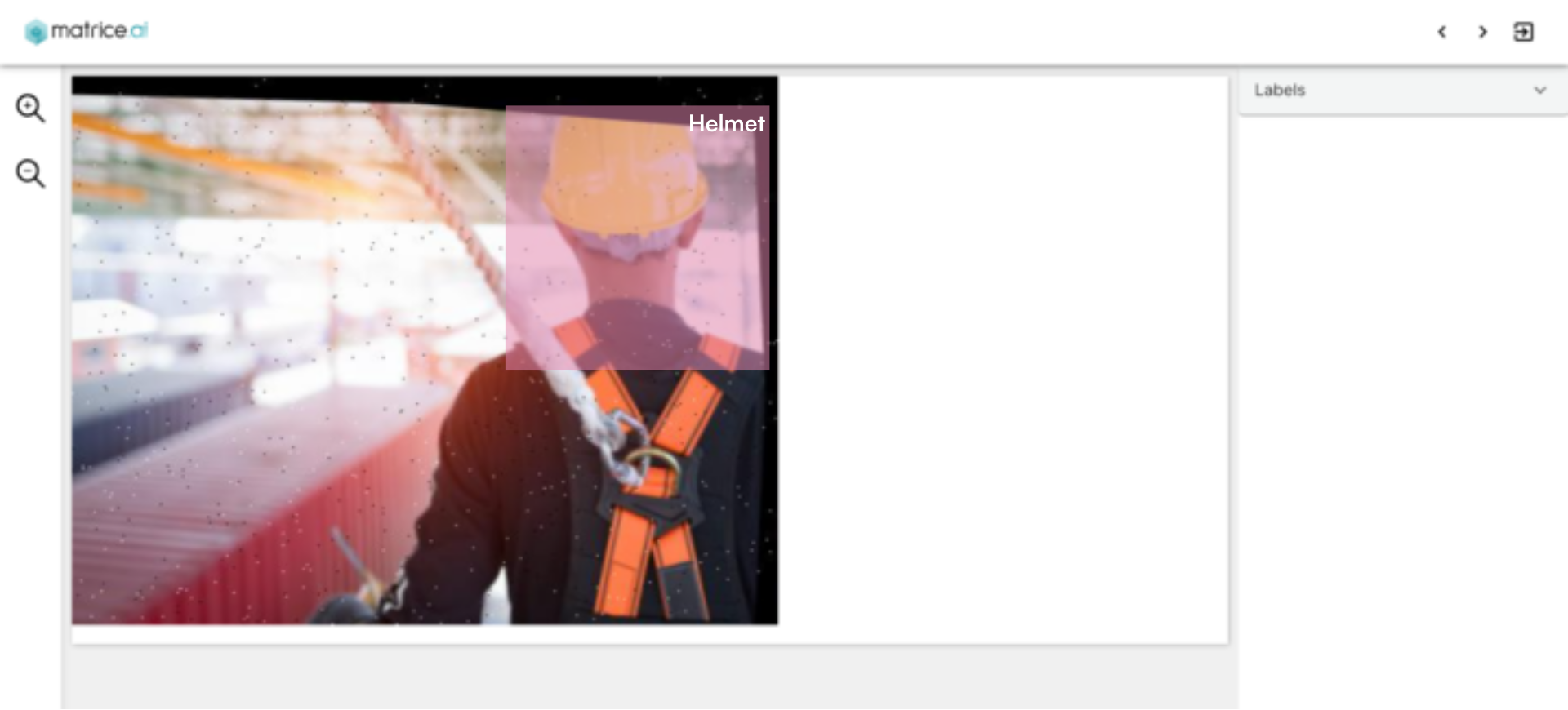

Our dataset was pre-annotated in the MSCOCO format, which is compatible with Matrice’s platform. This saved us time, allowing us to start training right away. If labeled data isn’t available, Matrice’s ML-Assisted Labeling tool can streamline the annotation process, automatically identifying and tagging instances based on preset criteria.

3. Preview of Annotated Image

Model Training

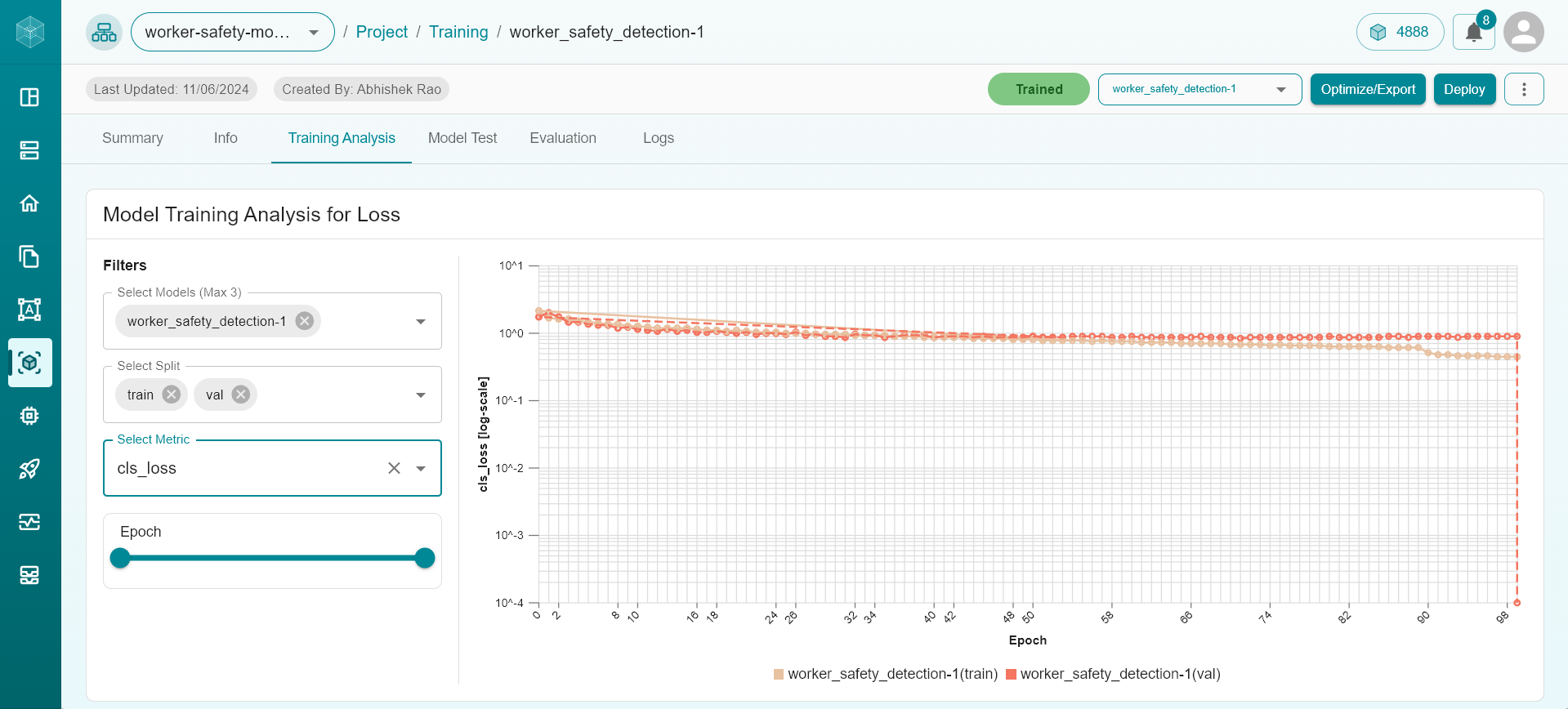

Using the YOLOv8 model, we ran multiple training sessions to optimize the model for safety detection tasks. After experimenting with various configurations, we found the following settings to work best for high accuracy:

Batch Size: 16

Epochs: 100

Learning Rate: 0.001

Momentum: 0.95

Weight Decay: 0.0005

4. Training Analysis for loss

These hyperparameters enabled our model to achieve a balance of precision and recall across all categories, ensuring consistent performance in identifying safety compliance and violations.

Performance Metrics

We evaluated our model on both validation and test sets, tracking key performance metrics like precision and recall. Below are some results from the model’s performance across different categories:

5. Percision for All the Classes

Category |

Precision (Validation) |

Precision (Test) |

Recall (Validation) |

Recall (Test) |

|---|---|---|---|---|

Wearing Helmet |

0.908 |

0.748 |

0.847 |

0.841 |

No Helmet |

0.602 |

0.667 |

0.182 |

0.25 |

Wearing Vest |

0.932 |

0.751 |

0.682 |

0.752 |

No Vest |

0.733 |

0.493 |

0.678 |

0.656 |

Person |

0.867 |

0.701 |

0.905 |

0.879 |

The model demonstrated high precision and recall, especially in critical categories like helmet and vest detection, which are essential for job site safety.

Model Inference

One of the standout features of our platform is the ability to export trained models to various formats, including ONNX, TensorRT, and OpenVINO. This flexibility allows the model to be deployed across diverse hardware configurations, from high-performance GPUs to lower-powered edge devices. For example, a worker safety detection model can be deployed on a low-powered device installed at a job site, making it possible to monitor safety compliance in real-time without needing substantial computing resources. Companies with more robust computing capabilities can deploy the model in formats optimized for high-performance environments to analyze data across multiple sites simultaneously.

Our platform offers an intuitive testing interface, allowing users to drag and drop images to view real-time model predictions. This feature provides quick insights into how the model detects safety compliance and violations, such as missing helmets or reflective vests, across different job site scenarios.

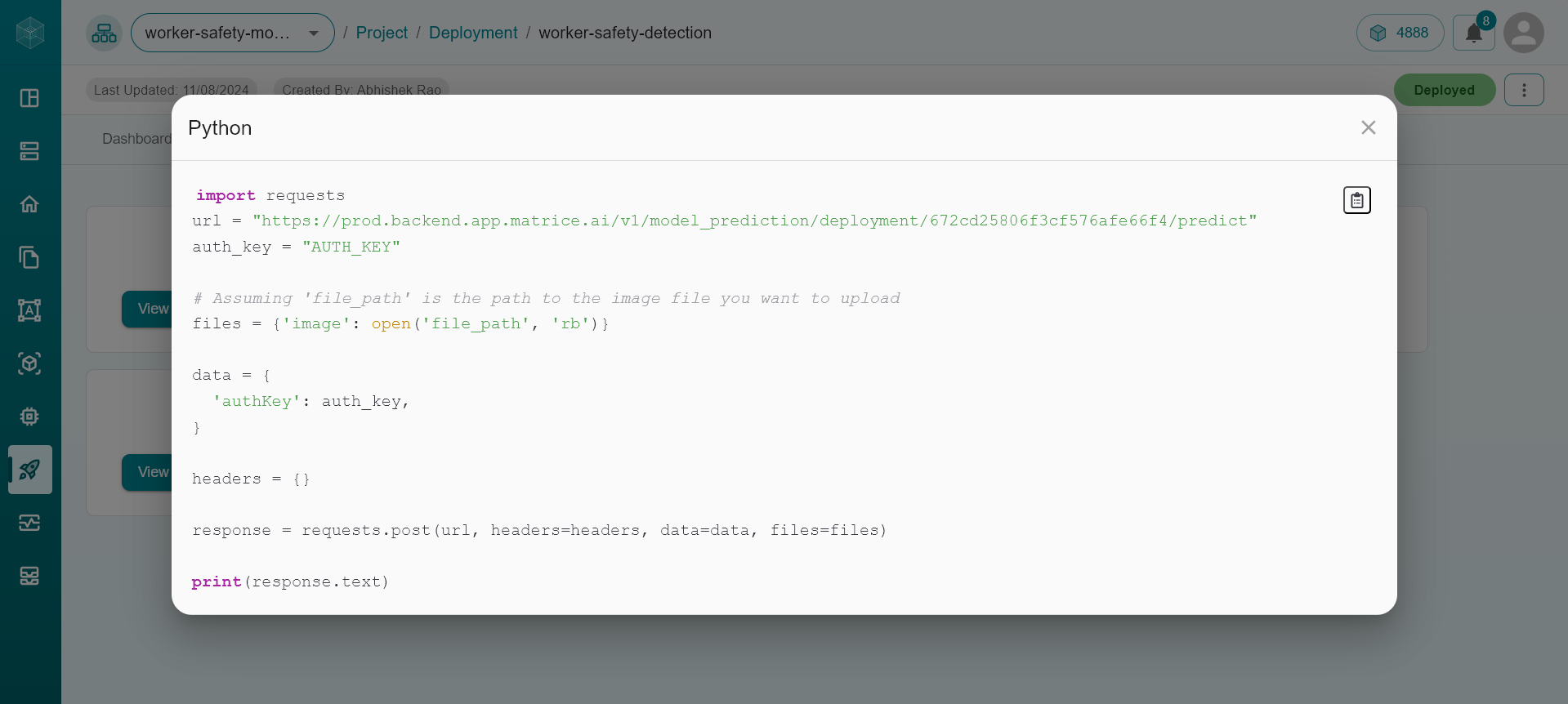

Model Deployment

With Matrice, deploying a model is seamless. Once the model is trained and evaluated, it can be deployed on our specialized servers, handling all computation on the backend. Users simply upload images, and predictions are returned almost instantly.

7. Example Code Preview for Python

The platform also provides API integration code for several programming languages, including Python, JavaScript, PHP, and Golang, ensuring flexibility for various applications. Whether integrating into a web service, mobile app, or custom software solution, Matrice makes deployment quick and efficient.

Real-World Applications

Construction and Manufacturing: In high-risk environments like construction and manufacturing, where heavy machinery and hazardous materials are common, the model can monitor for essential safety protocols, ensuring workers wear helmets, reflective vests, and other protective gear. This reduces accidents and improves overall safety compliance on-site.

Warehousing and Logistics: In busy warehousing environments, the model can track safety compliance, ensuring workers wear protective equipment and adhere to safe operating procedures around forklifts and heavy loads. Real-time alerts help supervisors address any safety violations immediately.

Insurance and Compliance: Insurance companies and safety auditors can use this model to verify that companies follow safety standards, potentially reducing liability. Companies demonstrating proactive safety measures may benefit from lower insurance premiums due to their commitment to risk management.

Conclusion

Worker safety is a pressing concern in high-risk environments. With Matrice’s no-code platform, building a worker safety detection model is straightforward, allowing organizations to implement a powerful safety monitoring solution. By deploying this model, companies can actively reduce safety risks, encourage protocol compliance, and foster a safer work environment.

From dataset preparation to model deployment, Matrice simplifies each step, making it easy to develop and deploy a robust worker safety detection system. Start your journey with Matrice today to take a proactive approach to job site safety and protect your workforce.

Think CV, Think Matrice

Experience 40% faster deployment and slash development costs by 80%