Smart Warehousing: Enhancing Efficiency with Pallet Instance Segmentation using YOLOv8s on Matrice AI

May 30, 2025

The modern warehouse is a complex, dynamic environment, pivotal to the success of supply chains. Accurate and efficient management of assets like pallets is critical. Traditional methods of tracking inventory often rely on manual checks or barcode scanning, which can be slow and prone to error. The advent of Artificial Intelligence, particularly in the realm of computer vision and instance segmentation, offers a transformative solution. Advanced models, developed and deployed using the Matrice AI platform, are now capable of revolutionizing how warehouses monitor and manage key assets like pallets, bringing unprecedented levels of accuracy and operational insight.

This blog delves into the critical role of pallet instance segmentation in warehouse environments, the implementation of a powerful YOLOv8s-based model for instance segmentation using the Matrice AI platform, and the significant operational benefits it delivers.

1. Why Warehouse Pallet Segmentation is Crucial

Accurate and real-time instance segmentation of pallets within a warehouse is fundamental for optimizing logistics and ensuring smooth operations. Key benefits include:

Enhanced Inventory Management: Enables precise, automated counting and location tracking of individual pallets, reducing discrepancies and manual effort. Segmentation can differentiate between palletized units for better stock visibility.

Streamlined Logistics Flow: Speeds up processes by accurately identifying pallet positions for automated guided vehicles (AGVs) or forklift operators, and verifying pallet movements.

Optimized Space Utilization: Provides data on pallet placement and density, aiding in better layout planning and ensuring optimal use of storage areas.

Improved Process Automation: Facilitates the automation of tasks like pallet receiving, put-away, retrieval, and dispatch verification through precise visual identification.

The ability to rapidly and accurately delineate individual pallet instances, even in cluttered or dynamic scenes, is key to unlocking next-generation warehouse efficiency.

2. Benefits of AI in Warehouse Pallet Segmentation

AI-driven instance segmentation systems, particularly those developed and managed on Matrice AI, offer substantial advantages:

Real-time Pallet Tracking: Continuous visual monitoring provides an up-to-the-minute overview of pallet locations and quantities.

Increased Accuracy in Counting & Localization: Minimizes human error in identifying and locating pallets, leading to more reliable inventory data.

Enhanced Throughput: Accelerates pallet handling processes by providing clear visual data to both human operators and automated systems.

24/7 Autonomous Operation: AI systems can monitor pallet movements and storage areas continuously, without fatigue.

3. Implementing Warehouse Pallet Segmentation with YOLOv8s on Matrice AI

Developing and deploying an effective pallet instance segmentation model involves careful dataset preparation, model selection, training, and evaluation – a process significantly streamlined by the comprehensive Matrice AI platform.

Dataset Preparation

The foundation of our high-performing model is the “warehouse pallet segmentation dataset (v1.0)”. This dataset was meticulously curated and managed using tools within the Matrice AI ecosystem to ensure robust learning for pallet instance segmentation:

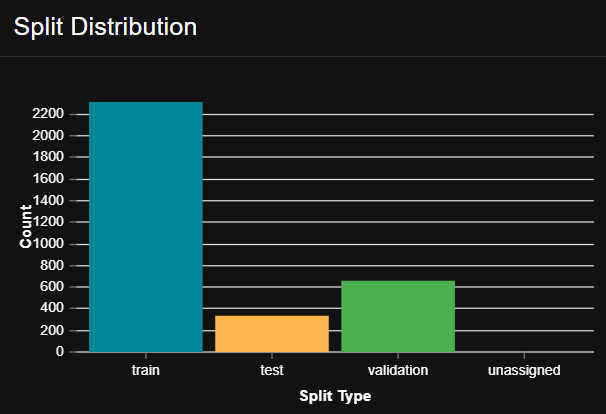

Composition: A comprehensive collection of 2314 training images, 662 validation images, and 331 test images.

Diversity: Features a wide array of pallets in various states (e.g., loaded, empty), under diverse conditions such as varied lighting, different camera angles, partial occlusions, and cluttered backgrounds typical of active warehouse environments.

Annotation Quality: Precise instance segmentation masks (polygons) for all target pallet instances.

Model Architecture and Selection

For this task, various YOLO-based architectures were considered for their balance of speed and accuracy in delineating object instances. The YOLOv8s architecture, adapted for instance segmentation, was ultimately selected as the primary model for detailed analysis due to its exceptional efficiency.

Model Focus: YOLOv8s (for Instance Segmentation)

Parameters: Utilizes an efficient 11.2 million parameter backbone.

Real-Time Performance: Designed for high-speed inference, suitable for live video stream processing.

High Accuracy for Segmentation: Achieves high-quality instance masks.

Efficiency: Optimized for deployment on various hardware, including edge devices.

Framework: Leverages the PyTorch training framework, fully supported on Matrice AI for seamless experimentation and training.

Comparative Model Performance

While YOLOv8s (for instance segmentation) was our focus, other models were also evaluated on the “warehouse pallet segmentation dataset v1.0”. Matrice AI facilitates such benchmarking to identify the optimal model for specific performance and deployment requirements.

Model |

Parameters (M) |

Test Precision (Pallets) |

|---|---|---|

YOLOv8s (Instance Seg) |

11.20 |

0.87 (approx. 0.874) |

YOLOv9c-seg |

27.90 |

0.86 |

YOLOv9e-seg |

60.50 |

0.86 |

The YOLOv8s variant demonstrated superior precision while having significantly fewer parameters, making it an excellent choice for resource-constrained edge deployments without compromising heavily on accuracy.

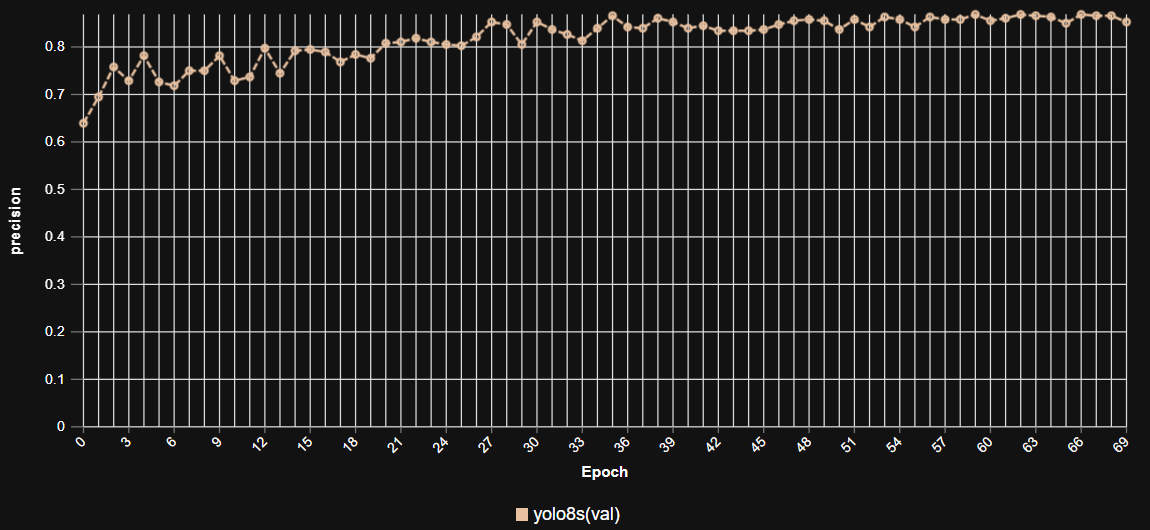

Training Parameters

The YOLOv8s-based instance segmentation model was trained using the following configuration, managed and fine-tuned on Matrice AI:

Parameter |

Value |

Description |

|---|---|---|

Model |

YOLOv8s (for Instance Segmentation) |

Adapted You Only Look Once version 8 Small |

Batch Size |

4 |

Number of samples processed before model update |

Learning Rate |

0.0001 |

Step size for optimizer |

Epochs |

70 |

Number of full passes through the training dataset |

Optimizer |

AdamW |

Adaptive optimizer with improved weight decay |

Momentum |

0.99 |

Optimizer parameter to accelerate gradient vectors |

Weight Decay |

0.0005 |

Regularization technique to prevent overfitting |

Cos_LR |

True |

Utilizes a cosine annealing learning rate schedule |

Target Runtime |

PyTorch |

The deep learning framework used |

Primary Metric |

Precision |

Key metric for evaluating pallet segmentation quality |

Model Evaluation (YOLOv8s for Instance Segmentation)

The chosen model’s performance in segmenting pallet instances was rigorously assessed on both validation and test splits of the “warehouse pallet segmentation dataset v1.0”. The results are summarized below:

Combined Model Evaluation Results (Pallet Instance Segmentation):

Metric |

Validation (Pallets) |

Test (Pallets - Primary Indicators) |

|---|---|---|

Precision |

0.86 |

0.87 |

Recall |

0.65 |

0.64 |

F1 Score |

- |

0.7391 |

mAP@50 (Mask) |

0.78 |

0.76 |

mAP@50-95 (Mask) |

0.61 |

0.60 |

F1 Score calculated as 2 * (Precision * Recall) / (Precision + Recall) for pallet segmentation on test results. mAP scores refer to mask Intersection over Union.

These results demonstrate the model’s strong capability in accurately segmenting pallet instances within warehouse settings. The primary metric, Precision, achieved an excellent 0.874 on the test set for pallet segmentation using the YOLOv8s variant.

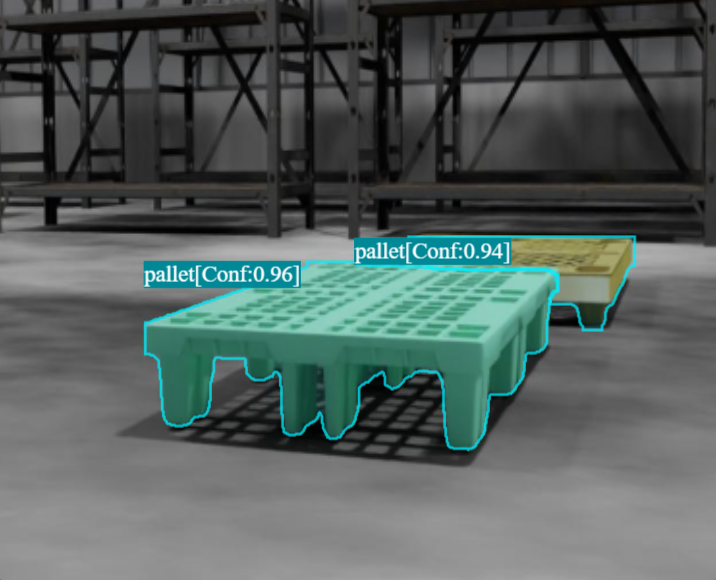

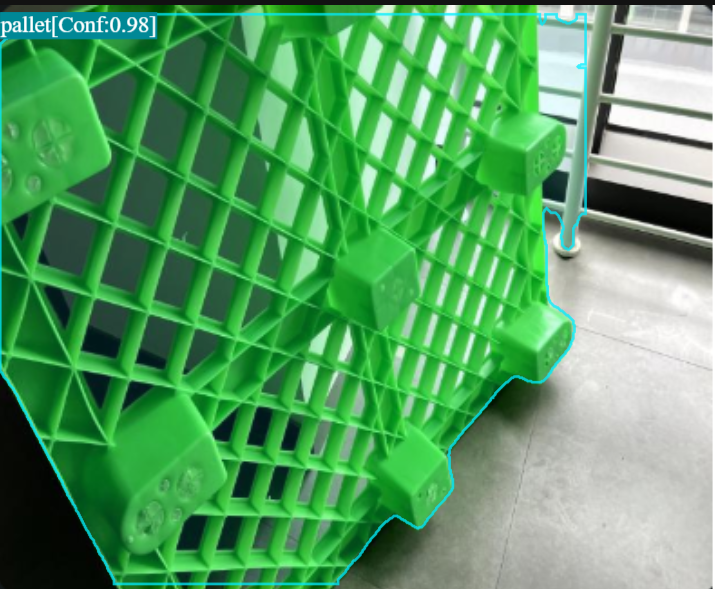

Model Inference Examples

Deployment Strategy

Effective deployment, managed via Matrice AI for streamlined MLOps, would involve:

Camera Integration: Strategic placement of cameras covering key pallet storage, movement, and processing zones.

Edge/Cloud Processing: Inference can occur on edge devices for low latency pallet tracking or on cloud servers for broader analytics, with deployment options available through Matrice AI.

Warehouse Management System (WMS) Integration: Segmented pallet data (location, count, instance ID) is fed into the WMS for real-time inventory updates and logistics planning.

Alerting & Notification System: Automated alerts for misplaced pallets, congestion in pallet zones, or count discrepancies.

Dashboard & Analytics: A visualization interface, potentially integrated with Matrice AI’s monitoring tools, for managers to track pallet flow, storage density, and overall inventory status.

4. Real-World Applications and Impact

The implementation of YOLOv8s for pallet instance segmentation, powered by Matrice AI, has tangible benefits across various operational facets:

Automated Pallet Inventory & Tracking

Real-time Pallet Counts: Continuous, automated counting of pallets in designated zones or across the facility.

Precise Location Tracking: Accurate localization of individual pallet instances minimizes search times and improves logistical coordination.

Reduced Discrepancies: Quickly identifies differences between system records and physical pallet counts/locations through visual verification.

Enhanced Pallet Flow & Logistics

Optimized AGV/Forklift Operations: Provides precise location data for guiding automated or manual pallet handling equipment.

Dock Management Efficiency: Tracks the arrival and departure of pallets at loading docks, streamlining receiving and shipping.

Reduced Bottlenecks: Identifies areas of pallet congestion to optimize flow and handling processes.

Improved Space Optimization

Storage Density Analysis: Segmentation data helps analyze how efficiently pallet storage space is being utilized.

Layout Planning: Provides insights for optimizing warehouse layouts based on actual pallet distribution and movement patterns.

5. Future Developments

The field of AI-driven warehouse automation for pallet management is rapidly evolving, with Matrice AI enabling quicker adoption of new advancements:

Distinguishing Pallet Load Status: Enhancing the model to differentiate between loaded and empty pallets based on mask characteristics or additional sensors.

3D Pallet Segmentation & Volumetric Analysis: Utilizing depth-sensing cameras for 3D instance segmentation of pallets to assess stack height or volume.

Predictive Analytics for Pallet Movement: Forecasting pallet demand in different zones or anticipating maintenance needs for pallet handling equipment.

Enhanced Integration with Robotics: Tighter coupling with robotic systems for fully autonomous pallet picking, sorting, and transportation based on segmentation data.

Anomaly Detection for Pallet Integrity: Training models to identify damaged or improperly stacked pallets from their segmentation characteristics.

Conclusion

The application of advanced computer vision models like YOLOv8s for pallet instance segmentation represents a significant advancement for the warehousing and logistics industry. By delivering accurate, real-time delineation of individual pallet instances, these AI systems substantially boost inventory management precision, streamline logistical operations, and enhance overall warehouse efficiency. The successful training and promising test results of this YOLOv8s-based model, developed and managed through the Matrice AI platform, underscore its capability to tackle complex, real-world warehouse challenges. As AI technology continues to evolve, its integration, facilitated by platforms like Matrice AI, will further unlock intelligent automation and data-driven decision-making in pallet handling and warehouse management worldwide.